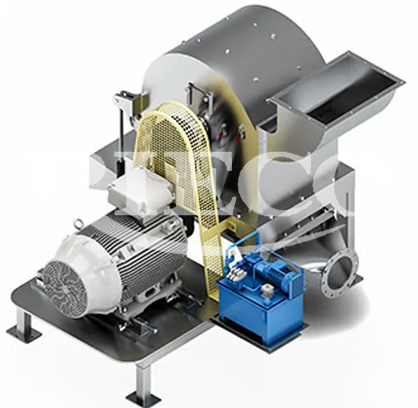

Universal Mill

Rieco presents the Universal Mill, engineered for unparalleled adaptability. Within a single housing, our mill grinds diverse materials to the desired fineness using interchangeable ROTOR + STATOR combinations. Its true universality shines with smooth transition between grinding tasks. Also known as the Pin or BT Mill, our design ensures vibration-free operations, self-feeding through a potent air current, and effective conveyance to collection points. Seamlessly integrate it with other machines for tailored solutions. Experience versatility and efficiency with Rieco's Universal Mill.

Operation

Materials enter from the feed hopper, guided by a screw or direct gravity, ensuring a consistent flow without overloading the mill. As the material meets the rotor's rotation, it gets drawn centrally, then flung outward by centrifugal force. During its outward trajectory, the material is finely ground between the rotor and stator, thanks to their unique interplay of impact and shearing actions. After passing the stator screen, the milled product is collected. The grinding fineness varies based on the product, rotor type, stator screen, feed rate, air intake, and rotor speed.

Models of Universal Mill

| Model | UM130 | UM220 | UM450 | UM800 |

|---|---|---|---|---|

| Main Motor HP | 2-3 | 3-10 | 15-40 | 30-75 |

| Max. Rotor Speed rpm for bar turbo & Pin rotor | 18000 | 1000 | 5150 | 2800 |

| Max. Rotor speed rpm for stud bar teeth rotor | 12800 | 7100 | 3650 | 2000 |

Types of Rotor-Stator Arrangements

Bar Turbo (BT)

Turbo Mill is well suited for efficient grinding to a high degree of fineness. The actual fineness obtained depends on the material, tip speed, the design of the sieve ring, size and shape of the sieve perforation as well as throughput of material and air. Tip speed of turbo mill ranges from 40-120 m/sec.

Inclined Bar Turbo (BT-SL)

Inclined Bar Turbo Mill can grind finer than turbo mill by virtue of inclined grinding bars, increase in the area of grinding baffles and reduction in open screen area. The maximum permissible tip speed is 120m/sec.

Stud Bar Teeth (SBT)

The Stud Bar Teeth mill is used either for grinding to medium degree of fineness or processing of the material containing hard or large pieces. In the SBT mill the material is ground in stages between the studs on the rotating grinding disc and teeth on the mill door before passing through the sieve. The maximum permissible speed is 80 m/sec.

Pin Bar (PNB)

For fine grinding, turbo mill, inclined bar or pin mills are used. The pin mill is used particularly for slight adherent products which otherwise clog the hole in the sieve ring. The maximum permissible speed is 120 m/sec.

Features

- Grinding rotors-stators are interchangeable.

- Rotors & stators are manufactured of wear-resistant steel.

- The mills being compact in size occupy reasonably low floor area.

- Unique & optimised mono-block rotors & stators design.

- Suitable for grinding material having a hardness of less than 3 Mohs.

- Compliance with industry standards for superior quality and reliability.

- Available in MS (Mild Steel) and SS (Stainless Steel) 304/316 material with wear protection.

- Can be adapted to suit various mountings, feeds, and discharge configurations.

- Available in four sizes of grinding chamber diameter of 130 mm, 220 mm, 450 mm & 800mm. These are suitable for the operations of small-scale to large-scale manufacturing.

- Flexibility to incorporate cryogenic grinding arrangement.

- Lower specific energy input (kWh/T) resulting in lower energy consumption.

Construction

- External Control Feed: Streamlined feeding process for enhanced efficiency.

- High-Efficiency Bag Filter: Fully automatic pulse jet cleaning ensures dust-free operation.

- Rotary Airlock: Acts as an air seal and aids in discharging material from the bag filter.

- Integrated Fan: Facilitates airflow through the mill and collector, enabling efficient product conveying.

- Control Panel: Offers sequential starting and stopping for the milling process.

Why Rieco?

in your process challenges.

Industries We Cater

Global Presence

We’re there for you

we are happy to answer