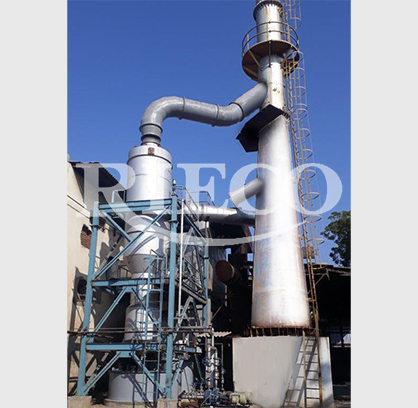

Dust Collection & Extraction System

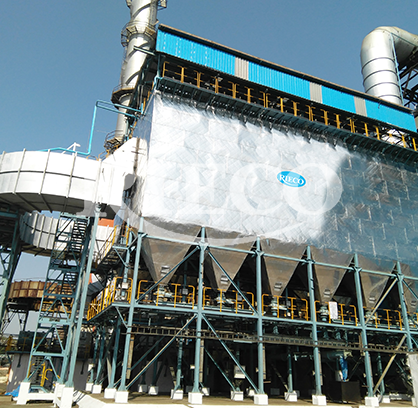

Bag Filter Construction

The Bag Filter comprises three primary sections:

- Plenum (Clean Air Chamber): The central component, or the "heart," of bag filter operations.

- Housing/Casing (Dirty Air Chamber)

- Hopper: Houses heavy dust particles.

Separating the plenum and housing is the bag plate or tube sheet, supporting the filter bags and cages – the actual filtering elements. The Bag Filter is a continuous, self-cleaning mechanism, able to sieve out particles even of submicron size from dust and gas flows.

With a straightforward design, the bag filter utilizes a pulsejet cleaning mechanism, powered by compressed air, ensuring remarkable dust cleaning efficiency.

The baffle plate shields the bags from the direct assault of dusty gases, causing most large particles to settle in the hopper. The finer particles move upward for further filtration via filter bags. Post-filtration, clean gases navigate through the plenum.

Working Principle of DE Systems

Dust sources within facilities, like conveyor transfer points or crusher vents, connect to the bag filter's inlet via ductwork. Depending on the application, suction hoods at these points might have manual or motorized dampers for airflow balance. These hoods link to a main duct header, which in turn connects to the bag filter.

Operation

Dust-laden air enters the Bag Filter, either through suction or pressure. As the air navigates through filter bags, dust remains on the bag surface, and clean air moves to the plenum and then out, driven by the centrifugal ID fan's suction.

As dust accumulates on the bag's outer surface, the pressure difference between dirty and clean air sections of the filter increases. A sequential timer then actuates a series of pulse valves at intervals, opening them and allowing a momentary high-pressure air flow. This process induces a secondary airflow, creating a pressure surge and reverse airflow through the bags, shedding the dust.

Our team, with 47+ years of vast experience and know-how, provides tailored solutions for various challenging applications. We design systems adhering to emission norms set by regulatory boards or specific client needs, considering various parameters and guidelines.

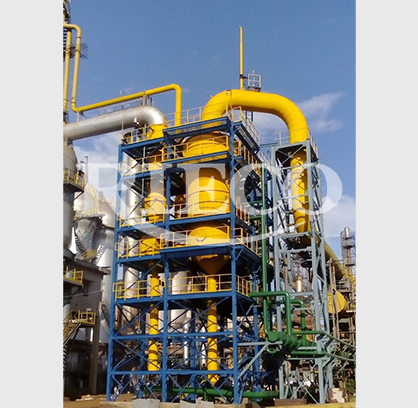

While Bag Filters are efficient, other options like electrostatic precipitators or scrubbers exist. Our experts can recommend the ideal pollution control equipment based on your requirements.

Why Rieco?

in your process challenges.

Global Presence

We’re there for you

we are happy to answer