Steam Sterilizer

Many dry products need to be pasteurised or sterilised. As a steam sterilizer manufacturer & supplier, we recognize that many traditional methods like irradiation, ozone, and UV are still used to sterilise dry products. Though these techniques may extend shelf life, they often compromise taste, flavour, consistency, and nutritional value. In contrast, steam sterilisation is the only efficient and globally recognised solution that preserves product integrity.

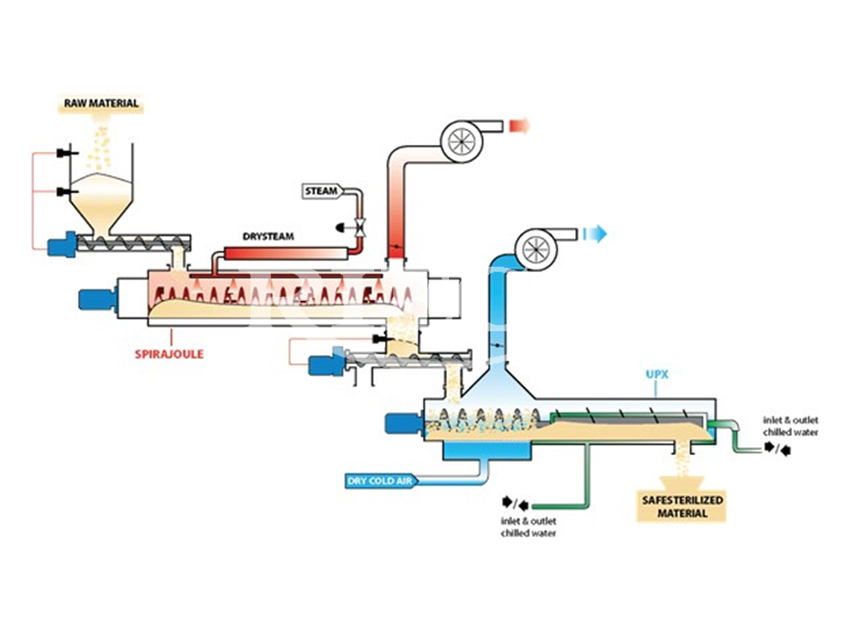

Safesteril Sterilizer was developed and patented by ETIA, a French engineering company founded in 1989. Safesteril technology is based on the unique and patented combination of an electrically heated conveyor with steam, that reduces germ content with a minimal alteration of its properties. It is an equipment that increases shelf life, by the killing/deactivation of bacteria available in dry products like yeast, mold, enterobacteriaceae, coliforms, salmonella, etc. keeping its natural properties intact.

We at Rieco are proud to enter a new era as a steam sterilizer manufacturer & supplier, bringing world-class sterilization technology from ETIA, France. The patented electrically heated screw reaches up to 250°C, ensuring the safe elimination of pathogens and dangerous microbes from spices and food products, in line with international safety standards. With systems installed in over 35 countries, Safesteril remains the preferred solution for continuous steam pasteurization and sterilization of all forms of dehydrated products—powder, granulated, crushed, chopped, flakes, whole, and more.

- Feed Hopper:(500L and 1000L capacity) Slow-motion dosing screw smoothly and continuously feeds the product into the sterilization chamber without breaking particles. As a steam sterilizer manufacturer & supplier, we ensure precise product handling from the first stage to maintain quality and consistency.

- Sterilization/Pasteurization: The product is gently conveyed through the chamber by a screw heated by Joule effect. Germ reduction is achieved due to the combination of the screw heat and the steam injected. Steam can be saturated or dry according to the treatment to be achieved, allowing perfect control of moisture. A transformer delivers the electrical power that heats the screw, reinforcing our expertise as a leading steam sterilizer manufacturer offering clean, efficient sterilization.

- Transfer / By-Pass Screw: The transfer screw is controlled by an exclusive “auto- reverse” feature, that guarantees only the product that reaches the target temperature and time conditions goes into the cooler. The product can be transferred into the cooling screw or bypassed in a bag for reuse.

- Dry Flash Cooling: The product is cooled down in a cold and dry atmosphere. Cooling is done by the action of a chilled water circulating inside the screw and the auger jacket. A dehumidified air is injected inside to get rid of the excess moisture. The material can be packed online, no need to regrind the powders.

- Safesteril is a versatile process that not only can perform pasteurization and sterilization, but also disinfect, dry and roast

- Safesteril achieves high performance of microbial load reduction, while maintaining the organoleptic properties of the products – taste, color and moisture are preserved.

- Volatile oil loss is less than 5-10%, which is less than with any other steam treatment systems.

- A 5-log reduction of Salmonella and a significant reduction of spores content are also guaranteed.

- During sterilisation 5 logs reduction for TPC and other germs including pathogens such as Yeast, Mold, Enterobacteriaceae (E.Coli), Coliforms, Salmonella are entirely inactivated.

- While sterilization in the process, SAFESTERIL makes sure to protect flavor, colour, consistency, nutrition, aroma and give maximum value.

- Baby food formula

- Organic foods

- Functional foods

- Lifestyle diets

- Spices and herbs

- Gourmet foods

- Healthy snacks

- International cuisine

- Spices

- Herbs & Botanicals

- Dehydrated vegetables

- Seeds, Nuts and dried fruits

- Cereals, Rice, Flours

- Cosmetics (clay, talc) and more…

Why Rieco?

in your process challenges.

Industries We Cater

Global Presence

We’re there for you

we are happy to answer