High Performance GMP Grade Mills

In the rapidly advancing world of pharmaceuticals, food processing, and chemical industries, precision, quality, and compliance with stringent regulations are non-negotiable standards.

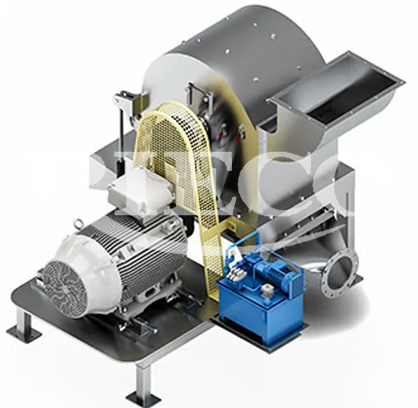

Our comprehensive range of GMP grade- size reduction machines are engineered to perfection, abiding by the Good Manufacturing Practice (GMP) standards. Whether it's the fine grinding maintaining the highest levels of hygiene, safety, and quality of pharmaceutical ingredients or the consistent reduction of food materials to the desired size, our GMP grade machines stand as a testament to innovation, reliability, and performance.

Join the ranks of satisfied customers who have discovered the unmatched quality of Rieco’s GMP Grade Grinding Machines.

Features

- Flame-Proof Motors and Electrical Instruments for safety protection.

- Full Coverage for Drives & Motors: Every drive and motor within our machines is fully covered, providing additional safety and reducing wear and tear.

- Hygiene Equipment Design: Specifically tailored for the pharmaceutical division, our machines prioritize hygiene, complying with the most rigorous industry standards.

- Food Grade Gaskets on Flanges & Joints: All flanges and joints are fitted with food-grade gaskets, enhancing integrity, and ensuring the utmost safety in food processing applications.

- Caster Wheels for Easy Movement: This allows for easy access and effortless mill movement whenever required.

- Superior Welding and Finishing Qualities: This not only enhances appearance but also resists any material accumulation in the welding joints, assuring smooth operation over time.

- Safety Sensors and Limit Switches: Equipped with Flame Proof (FLP) sensors and limit switches at the mill door, our machines come with an interlock for safety purposes.

- Material of Construction (MOC): Crafted completely in Stainless Steel with a mirror finish, our grinding machines boast a refined and hygienic appearance. The contact parts are built with SS 316, SS 316L, and Contact SS 304, ensuring a robust and corrosion-resistant design.

With Rieco's GMP Grade Grinding Machines, you are investing in a perfect blend of innovation, safety, and excellence.

Construction

- External Control Feed: Streamlined feeding process for enhanced efficiency.

- High-Efficiency Bag Filter: Fully automatic pulse jet cleaning ensures dust-free operation.

- Rotary Airlock: Acts as an air seal and aids in discharging material from the bag filter.

- Integrated Fan: Facilitates airflow through the mill and collector, enabling efficient product conveying.

- Control Panel: Offers sequential starting and stopping for the milling process.

- Clean in place (CIP) design.

Why Rieco?

in your process challenges.

Industries We Cater

Global Presence

We’re there for you

we are happy to answer