Tanker Unloading & Loading Systems

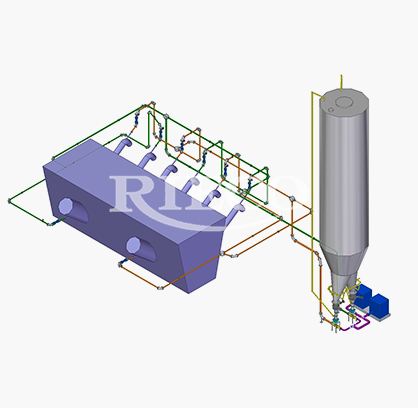

Our Tanker Unloading & Loading system is integral to continuous production, limiting manual intervention in handling small and jumbo bags, and reducing work zone emissions. Our approach involves utilizing tankers capable of unloading material via a pneumatic process, revolutionizing bulk handling of powders.

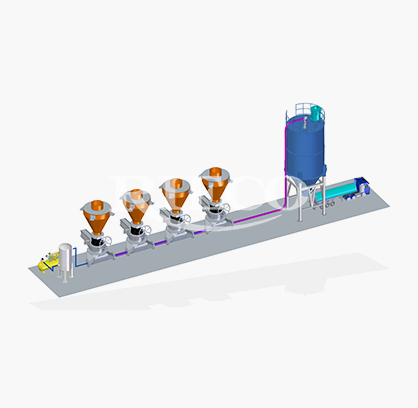

Tailored for dry bulk solids and powder material, our Tanker Unloading Systems facilitate direct transfer from the Tanker to your Storage Silos. Our systems can be configured to unload the tanker and fill Silos at capacities ranging from 10 to 50 TPH (tons per hour).

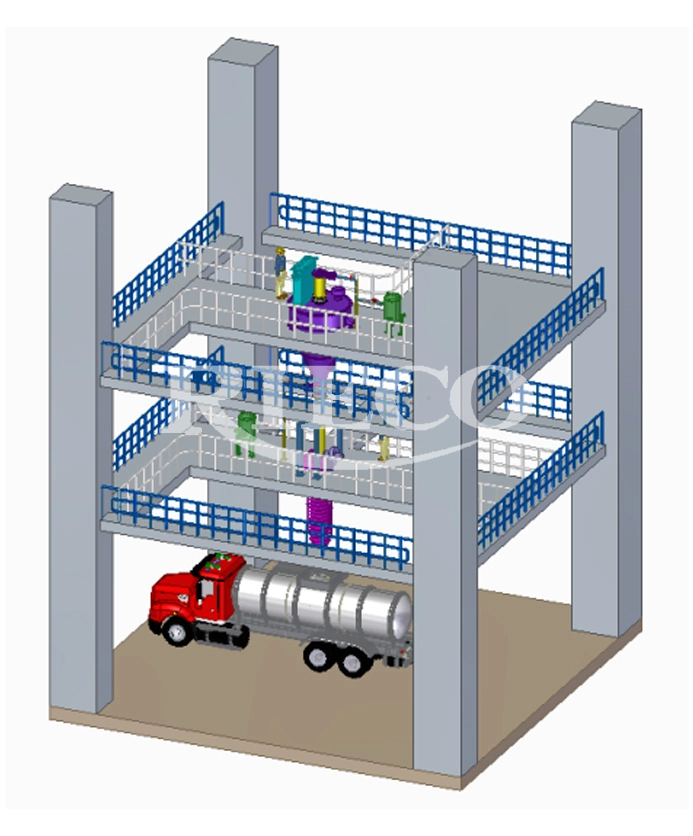

With the increasing demand for bulk powder handling from end users, the bulk powder supplier needs a Tanker/Bulker Loading System mechanism to unload the processed material directly into tankers without emissions while verifying the correct tanker weight. Our system accomplishes this swiftly, ensuring a seamless supply chain.

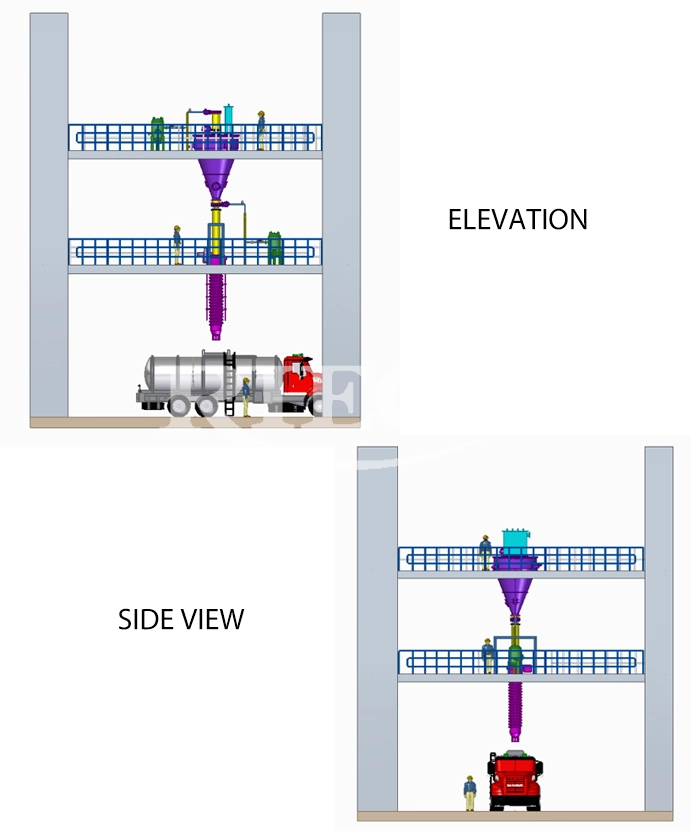

Loading bulk solids, whether in powder or granular form, is a routine operation in industrial plants. Our automated solution ensures a smooth process. Essential in bulk solid handling processes, our loading bellows (Telescopic Chutes) enable dust-free and secure loading of powdered and granular materials into tankers. They can be mounted underneath silos/bunkers, hoppers, or installed at the end of conveyors like screw feeders, elevators, or pneumatic conveying systems.

Our offering includes systems to load tankers/bulkers directly via pneumatic conveying and a special tanker loading device (Telescopic Gun). Open trucks can be loaded via a Pug mill/Dust conditioner, particularly useful in the Ash handling system.

Features

- Bulk Storage Support: Facilitating continuous production and reducing downtime.

- Automation: Minimizes manual intervention in handling small and jumbo bags, ensuring safety and efficiency.

- Customizable Capacity: Can be designed to fill silos with capacities ranging from 10 to 50 TPH (tons per hour), based on material characteristics and client requirements.

- Reduced Emissions: Ensures less work zone emissions, contributing to a cleaner and safer work environment.

- Avoid material contamination: this avoids material contamination since the system is closed and fully automated

- Automated Loading: Automated solution for dust-free and secure loading of powdered and granular materials into tankers.

- Special Loading Device: Incorporates a special tanker loading device (Telescopic Gun) for direct loading via pneumatic conveying.

- Weight Verification: Ensures the correct weight of the tanker while loading, promoting accurate supply management.

- Wheat Flour

- CaCO3

- Talc

- Bentonite

- Gypsum

- Limestone

- Kaolin

- Animal Feed

- Salt

- PTA powder

- Sinter dust

- Cement

- Starch

- Fly Ash

- Bauxite

- Perlite

- Marble powder

- Sugar

- Seed

- PVC

- Sodium sulfate

- Pellet plant dust

- Hydrated Lime

- PTFE chips

- Alumina

- Coal

- Minerals

- Quartz

- Corn

- Plastic pellets

- Dust collector dust

- ESP dust

- …..many more

Why Rieco?

in your process challenges.

Global Presence

We’re there for you

we are happy to answer