Dense Phase Pneumatic Conveying System

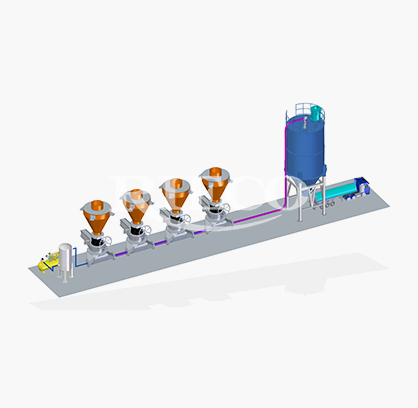

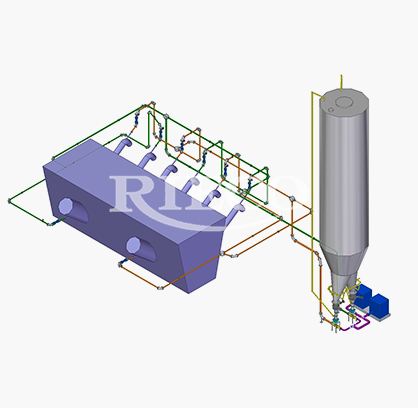

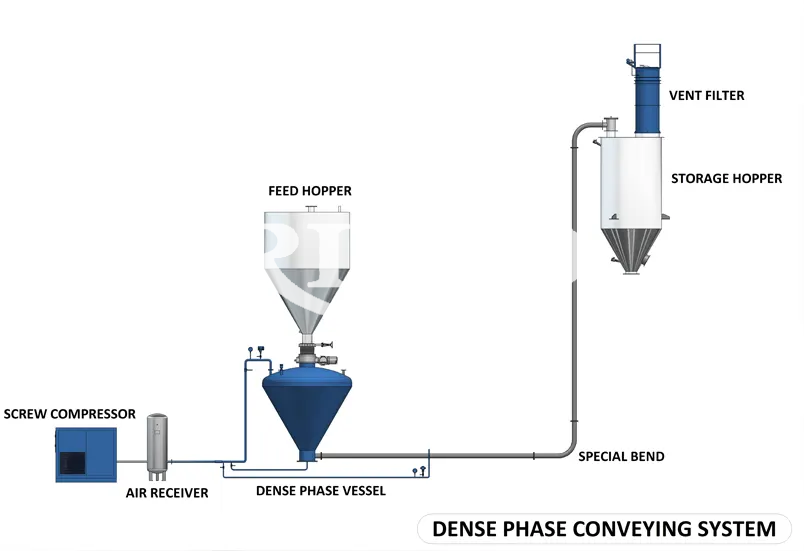

Our Dense Phase Pneumatic Conveying System offers an advanced and efficient method for transferring a variety of bulk solids such as powders, grains, flakes, and bulk solids. Utilizing high pressure and low velocity, our system ensures a high product-to-air ratio, making it ideal for conveying friable, fragile and abrasive materials with minimal degradation.

This makes them perfect for conveying bulk solids over long distances from single or multiple locations to various destinations. The low-velocity operation reduces wear and tear on both the system and the materials being conveyed, significantly extending equipment lifespan and maintaining product integrity.

Our Certifications

Why Choose Rieco's Dense Phase Conveying System?

- Our systems are engineered for conveying bulk solids over long distances

- Minimizes material degradation

- Reduces wear and tear. Perfect for handling abrasive materials

- We offer tailored solutions to meet the unique requirements of your process

- Our systems are suitable for a wide range of industries

- No material spillage, no dust emission, clean environment

- Handles wide variety of material such as fragile, abrasive, friable

- Minimum Maintenance

- Low Noise operation

- Low air flow rate

- Smart Automation with PLC, SCADA, IoT and AI

- Global installations, sale & service support

- Products used in the system are manufactured in-house

- Pneumatic system spares available in stock

Features

- Minimal material degradation as the material is transported at low velocity

- Handles wide variety of material such as fragile, abrasive and friable as well as materials with high bulk densities

- Minimum wear and tear of the system

- Minimum Maintenance

- No material spillage, no dust emission, clean environment

- Low Noise operation

- Low air flow rate

Application

Minerals

- Lime(Calcined, Limestone, Hydrated, Quick & Burnt Lime)

- Alumina

- Sodium Sulphate

- Pulverized Coal Dust

- Sinter Dust

- Pellet/Iron Ore Dust

Food

- Wheat Sugar

- Maida

- Soya Flakes

- ESP Dust

- Bag Filter/Fabric

- Filter Dust

Paint

- Hydrated Alumina

- Titanium Dioxide(tiO2)

- Dyes

- Black oxide

- Dust Collector dust

- Nylon 66 Chips

Foundry

- Chromite

- Bentonite

- Coal Dust

- Silica Sand

- Alkali Bypass dust

- Pet Coke

- CPC, Graphite Fines

- Quartz

- Iron Oxide

- Cast/ Stock House

- Copper/Concentrate

- Chalk Powder

Plastics

- Polyster Chips

- PET Chips

- HDPE/LDPE

- Polythylene

- PTA Powder

- Zinc Dust

- Lead Dust

- Zinc Phosphate

- Urea

- Silica Flux

- Gypsum/Calcium Sulphate

Other

- Fly Ash

- Cement

- Zinc Oxide

- MgO Powder

- Glass Batch Material

- Dolomite

- Soda Ash

- Roasted Copper

- Calcium carbide

- Sodium Chloride/salt

Why Rieco?

As your global partner, we fully immerse ourselves

in your process challenges.

in your process challenges.

48 +

Years of Experience

40 +

Countries

6000 +

Successful Installations

300 +

Strong Team

5 +

Global Partnerships

3

Manufacturing Facilities

Global Presence

We’re there for you

Feel free to ask us anything you have in mind,

we are happy to answer

we are happy to answer

Enquire Now

Close

Enquire Now