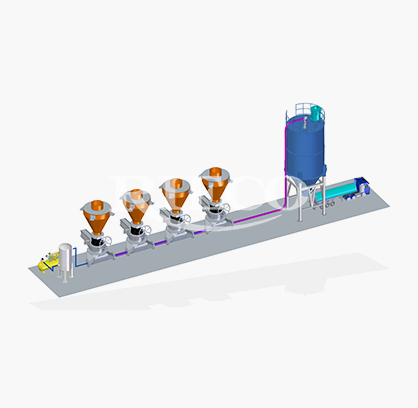

Closed Loop Pneumatic Conveying Systems

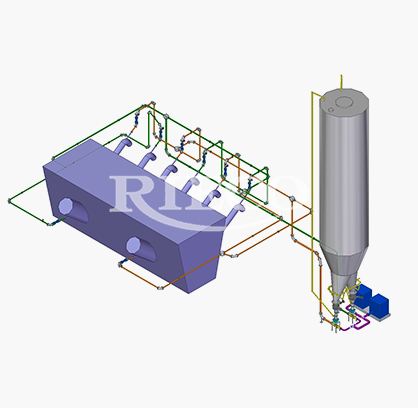

Our Lean Phase Closed Loop Pneumatic Conveying System, based on Nitrogen (N2), is a widely trusted solution for the transport of materials with potentially explosive, hazardous, neurotoxic, or toxic properties. Our innovative system circulates N2, utilizing a small quantity to convey material under low pressures. It ensures a preset oxygen level is maintained throughout, providing a safe and efficient transportation mechanism.

This type of system, even without N2, is also ideal for handling carcinogenic, pneumoconiosis dust, and pharmaceutical applications.

It guarantees zero human interference and a closed, secure environment for powder handling. With over 45 years of experience, we customize our trusted systems to various industrial needs, domestically and internationally.

Features

- Expertise in Handling Hazardous and Explosive Materials: Lean Phase Closed Loop Pneumatic Conveying systems are equipped to deal with hazardous and explosive materials with precision and safety. Nitrogen-based conveying systems reduce fire or explosion risks by lowering oxygen content in the pipeline.

- Leak-Proof System: The closed-loop design ensures that no materials escape during transportation, providing a leak-proof solution that protects both the environment and workers.

- Offering Customized Solutions: The system can be tailored to meet specific industrial requirements and individual needs, ensuring optimal efficiency and functionality.

- Energy Efficient: Designed with energy conservation in mind, Lean Phase Closed Loop Pneumatic Conveying operates with minimal energy consumption, reducing operational costs.

- Safer Working Environment: The inherent safety measures of this system minimize risks, providing a more secure working environment for personnel.

- Maintain Product Quality and Integrity During Transportation: With its enclosed and controlled environment, the system ensures that the product is transported without loss of quality or integrity, preserving its original condition.

- Reduces Risk of Fire and Explosions: By handling potentially explosive and flammable materials in a controlled and closed environment, the system greatly diminishes the risk of accidents like fires and explosions.

- Oxidation Prevention: These systems create an oxygen-free environment to prevent chemical reactions or degradation due to oxidation.

- Product Quality Preservation: By reducing moisture content, these systems ensure the quality and integrity of hygroscopic or moisture-sensitive materials.

- Protection of Sensitive Materials: These systems maintain a clean atmosphere, preserving purity and preventing contamination in sensitive industries like pharmaceuticals or food processing.

- Process Control: The systems offer precise control over the conveying process by adjusting the nitrogen flow and pressure to meet specific flow rates and performance requirements.

- Flammable Materials

- Reactive Materials

- Toxic/Hazardous Substances

- Fine Dust/Powders

- Hygroscopic Materials

- Flammable Materials: Substances like gases, liquids, or powders with low flash points or that form explosive mixtures pose significant risk during pneumatic conveyance.

- Reactive metals, strong oxidizers, or unstable compounds that undergo violent reactions when exposed to air or moisture can be hazardous.

- Pneumatic conveyance can be risky for toxic, corrosive materials or substances that generate harmful fumes or dust.

- Combustible dusts can lead to dust explosions if ignited, while some powders pose health risks when inhaled.

- These absorb moisture from air, leading to clumping, clogging, or undesirable reactions during pneumatic conveyance.

Why Rieco?

in your process challenges.

Global Presence

We’re there for you

we are happy to answer