Pneumatic conveying, representing the backbone of bulk material handling systems, is where our expertise truly shines. Whether it’s a simple system or achieving great performance with difficult transport materials, our in-depth knowledge and comprehensive understanding of the complex behaviour of bulk materials, coupled with advance powder testing and analysis to scientific way of negative/positive air pressure conveying system design, have earned the trust of our customers. To fulfil elevated demands of the industry for extensive product capacities, greater product variability and major conveying distances, Rieco continually strive to develop innovative pneumatic vacuum conveying systems and components with a wide selection and range.

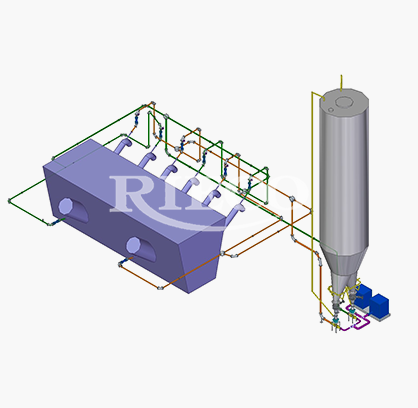

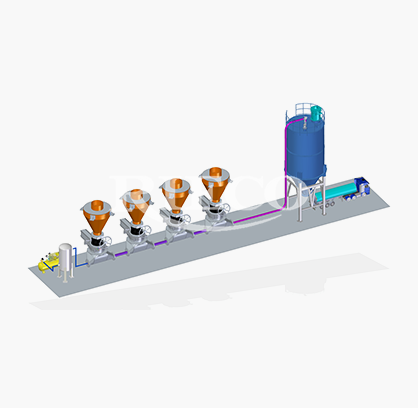

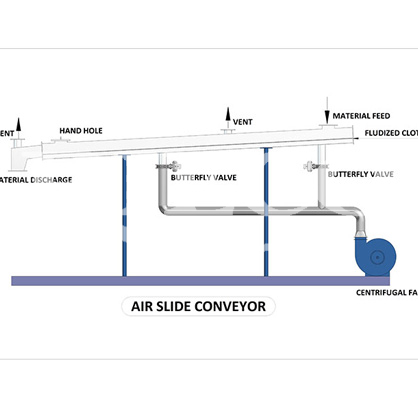

Bulk Material Handling systems through pneumatic conveying are used in Industries to transfer dry bulk solids and powders from one location to single and/or multiple locations. It is convenient for huge volumes at a much faster rate and with critical layouts. Material handling systems are designed as per specifications and suitability of wide range of industries.

Safety of workers, hygiene and management of hazardous powders are some of the continued challenges in any given industry. Pneumatic conveying system is beneficial where space and layout seems to be a constraint & where mechanical or other forms of conveying is not possible.

With over 48 years of experience and expertise, RIECO masters in designing, planning, manufacturing and successfully commissioning optimized, efficient, and cost-effective pneumatic conveying systems, both dilute phase and dense phase. We have successfully commissioned completely automated Turnkey projects in Chemicals, Plastics, Pet Food, Cement, Steel, Fertilizers, Food, Metals and various other industries. Our strong & continuous research coupled with experience can assist you in selecting the right solutions for your process requirement. We are well positioned to offer solutions for Food industry complying with global health, hygiene, and safety standards.

Our comprehensive material handling vaccum systems include a variety of pneumatic conveyors tailored to meet diverse industrial needs. From dense phase conveying to dilute phase systems, our solutions cover the full spectrum of conveying requirements. We ensure efficient transport along the conveying line, ensuring optimal performance and reliability throughout the process. Our adaptive technologies ensure that our products are always poised to meet the needs of tomorrow!

Applications of our Pneumatic Conveying Systems

- From single component to complete systems for bulk material handling, Rieco design and manufacture equipment for the pneumatic transport of bulk solids materials for small and large systems.

- We specialize in optimizing solutions for critical materials like explosives, abrasives, toxics, and carcinogens, ensuring safe pneumatic conveying without human intervention.

- Our pneumatic conveying systems are ideal cover a wide range of applications and come with ATEX certifications for compliance.

- Services include complete systems engineering for pneumatic conveying applications, renowned powder testing and analysis, inhouse manufacturing of key components, spare parts provisioning, and comprehensive field services.

- With decades of experience, we excel in designing reliable types of pneumatic conveying systems for conveying challenging materials such as attrition-sensitive, abrasive, sticky, hygroscopic, or fragile products.

- We offer simple and cost-effective solutions for efficiently handling and moving bulk dry materials through pneumatic conveying over long distance.

- Our pneumatic conveying systems feature excellent control capabilities, including custom supervisory controls, and integrate cutting-edge technology from Rieco.

- Integrated designs encompass automatic bag emptying machines, manual bag dump stations, jumbo bag unloading systems, feeders, powder transfer systems, and various components like, diverter, slide gate, and rotary valves.

- We provide ATEX, CE certified solutions tailored to applications with high sanitary requirements, meeting customer and government specifications, including validation requirements for the food and pharmaceutical industries.

Why Rieco?

in your process challenges.

Global Presence

We’re there for you

we are happy to answer