Spark Arrestor

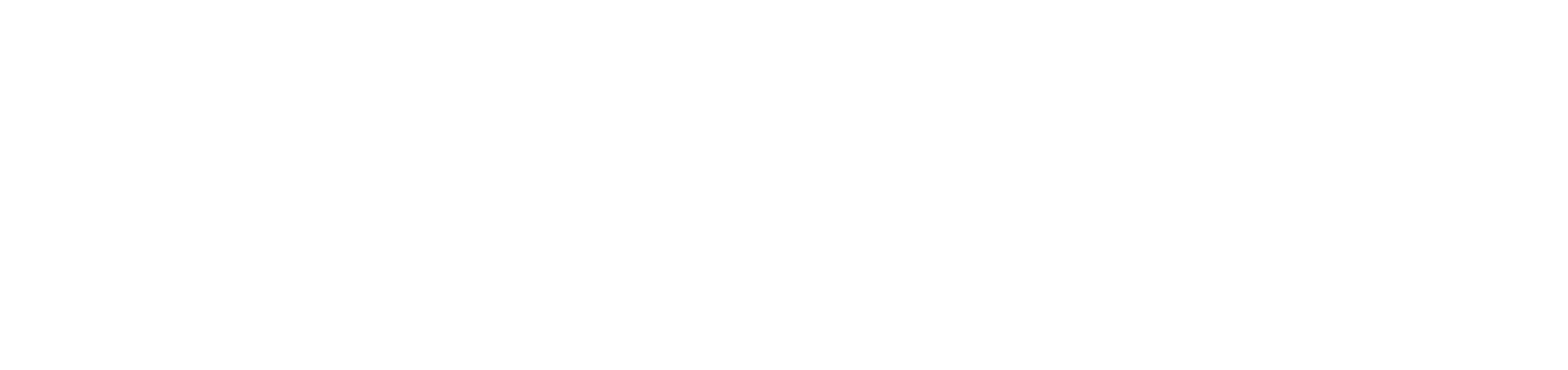

Within the complex realm of industrial machinery, the spark arrestor stands as a crucial guardian against fires. These devices intercept and neutralize sparks, preventing potential disasters in equipment. By introducing turbulence through their strategically positioned vanes, spark arrestors transform dangerous sparks into harmless ash, subsequently collected in a dedicated chamber.

Moreover, spark arrestors double as pre-separators, reducing the load on primary dust collectors. In certain industries, their presence is non-negotiable, safeguarding ducts from spark-induced damage and combustible material ignitions.

In essence, spark arrestors are the silent protectors of industrial safety, ensuring smooth, hazard-free operations.

How It Works?

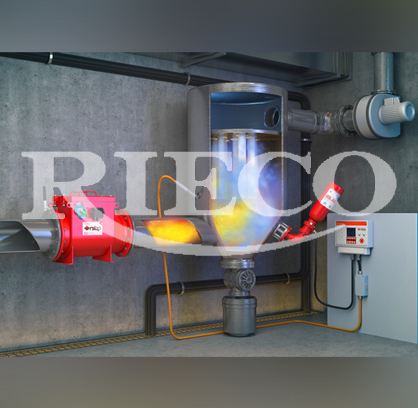

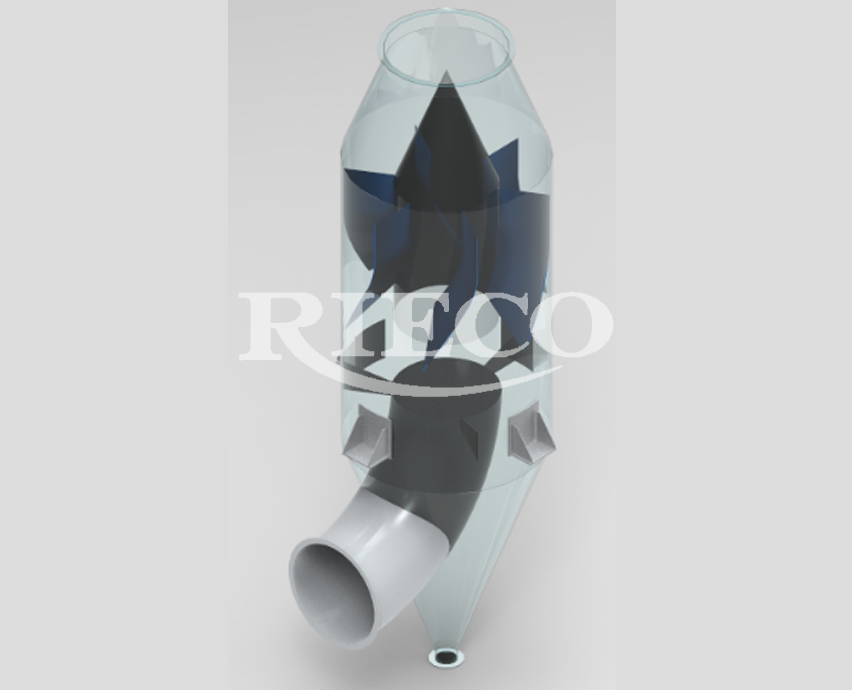

The spark arrestor functions by transforming incoming laminar flow into turbulent flow. As the flow enters the spark arrestor, it encounters a series of carefully designed vanes that ensure every particle, including sparks, makes contact. There are no gaps in the vane arrangement, so no spark can escape the impact.

The conversion of laminar flow into turbulent flow assists in separating ash or dust from the rest of the flow, based on density differences. As the flow spins, high-density particles like ash are separated from the low-density flow and collected in a hopper. A rotary airlock valve beneath the hopper then enables easy discharge of the collected dust or ash.

The remaining air, now spark-free, continues through the system. Thus, the spark arrestor not only neutralizes sparks but also serves as a pre-separator and pre-dust collector, reducing the dust load in the primary bag house.

Features

- Reduces Dust Load: It minimizes the dust load on the bag house, enhancing overall system efficiency.

- Highly Efficient in Destroying Sparks: It's designed to neutralize sparks effectively, keeping the system safe.

- Minimizes Risks by Cooling Gas: By cooling the gas before it reaches the filter surface, the risk of ignition is reduced.

- Reduces Risk of Explosion: It acts as a protective barrier, preventing explosions within the process or system.

- Easy Access Clean-Out Door: This feature allows quick and convenient access to empty any accumulated material.

- Low Maintenance with 'ZERO' Moving Parts: Its static design ensures minimal wear, leading to reduced maintenance needs.

- Customizable Sizing: With a large database, it enables the selection of precisely sized spark arrestors according to industrial applications and user requirements.

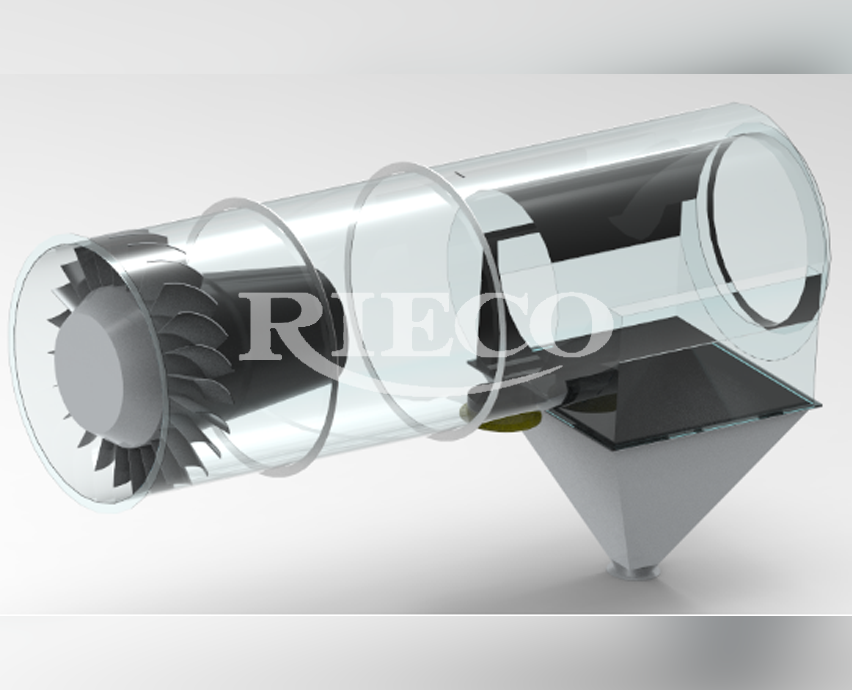

- Versatile Installation Options: It can be installed in either horizontal or vertical configurations, offering flexibility.

- Range of Sizes: Standard sizes range from Dia. 400 mm to 2000 mm, with options available to meet specific needs.

- Compact Design: Suitable for space constraints, the design ensures it can fit into various setups.

- Liner Flow with Least Back Pressure: Designed to maintain smooth flow and minimize back pressure, optimizing system performance.

These features collectively contribute to the spark arrestor's vital role in maintaining safety and efficiency within industrial processes.

Why Rieco?

in your process challenges.

Industries We Cater

Global Presence

We’re there for you

we are happy to answer