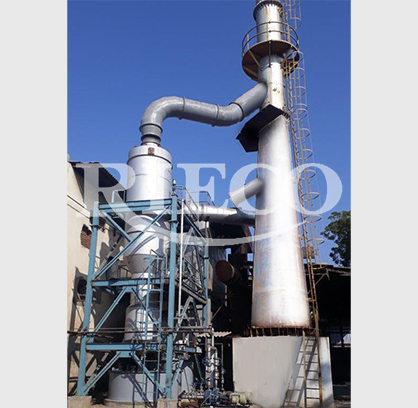

Fumes Extraction System

Rieco's Fumes Extraction Systems (FES) are a beacon of modern air pollution control. Designed to combat the hazardous emissions from heat processes, our systems efficiently capture high-temperature fumes through specially crafted suction hoods. These fumes are then treated, often cooled, and passed through our unique spark arrestor, which not only handles sparks but also acts as a pre-dust collector. The result? Significantly reduced emissions and a cleaner working environment.

Tailored to individual site layouts and application needs, Rieco's FES meets both Indian and international emission norms. Simple, customizable, and effective, our FES is the gold standard for a safer, dust-free, and clean air in the workspace.

Rieco’s fume extractor rapidly captures all the dust particles using compressed air for powerful suction to effectively collecting contaminants.

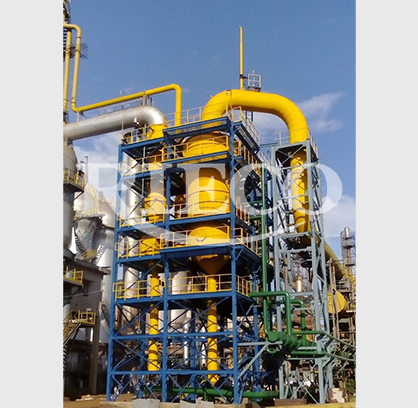

How It Works?

- Smoke Collection Hood: The Furnace features a Low Hood Design for smoke collection, ensuring no fugitive gas emissions escape unchecked.

- Direction to Smoke Chimney: Emissions from the furnace are channeled by the smoke collection hoods directly into a smoke chimney or stack using natural draft.

- Butterfly Valve Integration: Positioned just above the smoke hood's top, the butterfly valve plays a crucial role in guiding the gas emissions to the Air Pollution Control equipment.

- Powerful I.D. Fan: Post the butterfly valve, these gases are harnessed by a potent Induced Draft (I.D.) fan and directed towards the Pollution Control Equipment.

- Spark Extinguishing: If sparks are present in the gas stream, they are typically extinguished in the ductwork, bends, and within the Heat Exchanger (Forced Draft Cooler) due to directional changes.

- Cooling via Forced Draft Cooler: Gases first journey through a tubular forced draft cooler. Here, atmospheric air is blown over tubes using axial cooling fans, which cools down the gases. This process allows the heavier particles within the gases to settle at the cooler's bottom.

- Multi-Chamber Bag Filter System: The gas, now with fewer heavier particles, progresses to a multi-chamber Bag Filter System. It's essential to note that the I.D. fan is located post this system.

- Dust Filtration: As the gas flows through the filter bags, any lingering dust gets effectively trapped by the bags, ensuring only clean gas emerges from the Bag Filter.

- Release of Clean Gas: The purified gas, now rid of its contaminants, is safely released into the atmosphere through a stack.

In essence, Rieco's FES for fume filtration offers a comprehensive and efficient solution for ensuring that only clean, purified gas makes its way into our atmosphere.

Features

Bag House Cleaning

- Both online and offline cleaning mechanisms are incorporated, ensuring a thorough and efficient cleaning process.

- Offline Cleaning: With one compartment isolated, the system performs bag house cleaning "OFF LINE".

- On-Demand Activation: Based on the pressure drop across the bag house, cleaning is initiated. If the pressure exceeds the set point, the master controller engages.

Tapping Fumes Fan (Booster Fan)

- Designed specifically for each furnace, the fan operates under both positive and negative pressures.

- Efficiently extracts fume dust from the tap hole and directs them to the bag filter.

System Isolation

- Isolation Damper with Actuator: This feature ensures the entire system can be isolated when needed.

- Furnace Stack Dampers: Used for venting gases, especially handy if flue gas temperatures are extremely high after dilution damper engagement.

- Maintenance Isolation: Should there be a need for maintenance, the entire Gas cleaning plant can be isolated using the provided actuated dampers near the furnace hood.

Smoke Collection Hood Varieties

- The system offers diverse types of Smoke Collection Hoods including swiveling types and side draught hoods, ensuring compatibility with different site layouts.

Optimized Power Consumption

- Due to minimized pressure drops, the system ensures energy efficiency and reduced power consumption.

Customization

- Every solution is tailored to align perfectly with the site layout and specific process requirements.

High-Temperature Handling

- The FES is adept at managing high-temperature flue gases, ensuring efficient purification.

Design Flexibility

- The system is designed for convenient online maintenance of Bag Houses.

Application

- Induction Furnace

- Blast furnaces

- Electric Arc Furnace

- Argon Oxygen Decarburization

- Laddle Refining Furnaces

- Exothermic reaction

- furnace

- Incineration Klin

- Hazardous waste plant

- Medicinal waste incineration

- Aluminum Smelting Furnace

- Copper Smelters

- Anode Furnace in copper industry

- Lead Rotary furnaces

- Ferro Alloy furnace

- Calcium carbide furnace

Why Rieco?

in your process challenges.

Global Presence

We’re there for you

we are happy to answer