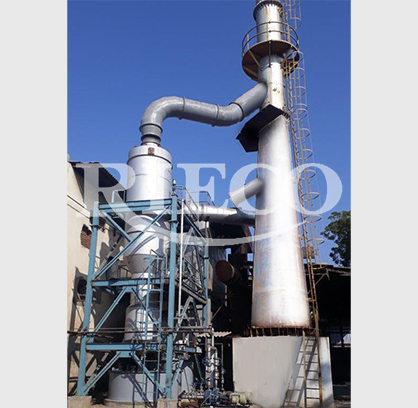

Forced Draught Heat Exchanger

RIECO's Forced Draught Heat Exchanger, a cutting-edge solution designed for cooling hot, dust-laden gases in various industrial settings. Utilizing a tubular air-to-air cooling mechanism, our system not only efficiently lowers the temperature of the gases but also filters out heavier dust particles. This innovation reflects RIECO's commitment to both excellence in engineering and environmental responsibility.

How RIECO's Forced Draught Heat Exchanger Works?

- Gas Entry: Gases laden with dust begin their journey from their source, entering the heat exchanger from the top inlet.

- Cooling Process: Once inside, these hot gases are directed through a series of vertical tubes that make up RIECO's uniquely designed Tubular Forced Draft Cooler.

- Atmospheric Cooling: Simultaneously, an axial flow fan propels atmospheric air over these tubes. As the air blows across the surface of the tubes, it draws away the heat, effectively cooling the gases inside.

- Dust Settling: Thanks to the design and flow dynamics, heavier dust particles within the gases naturally settle at the bottom of the cooler.

- Cleaner Gas Release: After this dual process of cooling and cleaning, the gases are then safely released or directed to the next stage of the process.

In essence, RIECO's Forced Draught Heat Exchanger offers a streamlined and efficient method for cooling gases while also reducing their dust content, ensuring optimal performance and environmental safety.

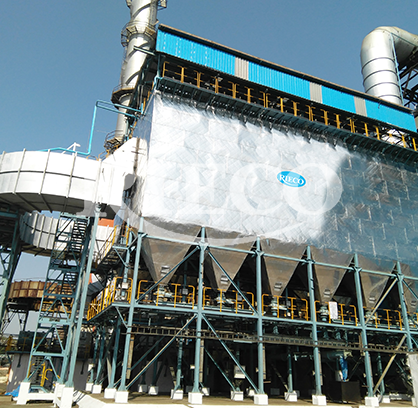

- Bolted Tube Packets: Incorporating a German-inspired design, we offer complete bolted construction of tube packets. This modular construction facilitates easy assembly and erection at the site. The bolted construction, combined with provisions for slotted holes, adeptly handles the thermal expansion of the entire tube assembly.

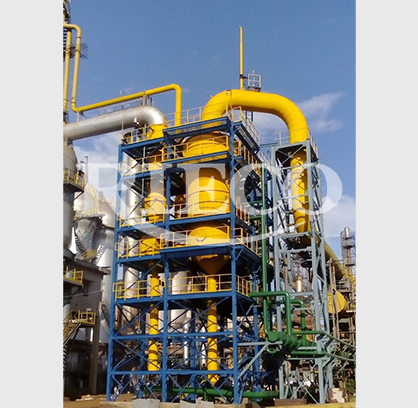

- Industry Collaboration: We've joined forces with renowned experts in the heat exchanger and boiler industry. Leveraging their deep expertise, we guarantee selections optimized for thermal efficiency and operating cost.

- Heat Recovery Systems: Armed with detailed information about gas composition and temperature patterns, RIECO is equipped to design heat recovery systems tailored for power generation or feed material drying applications.

- Dust Collection Capability: Integrated design allows for the collection of heavier dust particles, thereby enhancing the purity of the cooled gases.

- Eco-friendly Design: By minimizing energy consumption and effectively filtering out contaminants, this heat exchanger contributes to more sustainable and environmentally friendly operations.

- Maintenance Accessibility: Thoughtfully engineered for ease of access, ensuring that routine maintenance and inspections can be carried out with minimal downtime.

- Compatibility with Various Gases: Engineered to handle a wide range of gas types, including highly dust-laden ones, providing a versatile solution for various industrial applications.

- Robust Construction: Built with durability in mind, ensuring long-term performance even in the most demanding industrial environments.

- Seamless Integration: Designed to easily integrate with existing systems and processes, allowing for a smooth transition and minimal disruption to ongoing operations.

- Cost-Efficient Operation: Through its energy-efficient design and robust construction, it offers a cost-effective solution for cooling and cleaning gases, making it a valuable addition to any industrial setup.

- Compliance with Standards: Manufactured in adherence to international quality and safety standards, assuring reliability and safety in operations.

These features collectively define RIECO's Forced Draught Heat Exchanger as a cutting-edge, versatile, and reliable solution tailored for modern industrial needs.

Why Rieco?

in your process challenges.

Global Presence

We’re there for you

we are happy to answer