Importance of Explosion Protection System

Electrostatic Precipitators (ESPs)

Every business and place of work relies on safety. Be it financial safety, social safety, or physical safety. It is something companies need to proactively focus on so that no regrettable accidents occur in the future.

Industrial safety should be and is the topmost priority for most enterprises, factories, and industries. Be it cottage industries or large-scale manufacturing plants, it is the duty of every business owner to ensure safe working conditions to protect the lives of the people working and assets present on site.

What is Factory / Industrial Safety?

Industrial safety systems are countermeasure systems that come into action if there is a mishap, accident, explosion, fire, or if the process control systems fail. These safety systems aim to eliminate the causes of accidents wherever possible. When elimination is not possible, safety systems shield against hazards using guards, enclosures, safety valves, interlocks, and similar arrangements.

The Factories Act of 1948 lays out a robust set of guidelines to help industries ensure their sites are safe places to work. Factory safety commonly covers:

- General safety

- Safety from mechanical equipment

- Safety from electrical equipment

- Safety from explosive / radioactive material

- Safety from hazardous chemicals / pollutants

In this blog we will specifically focus on fire and explosion damage, its technicalities, and how one can safeguard against such mishaps.

Importance of Explosion Protection Systems

Precautionary measures that prevent explosions and fires are extremely important, as the lack of them can result in loss of property, money, assets and—most importantly—lives. The damage a volatile fire can cause around sensitive materials and equipment may take months, if not years, to recover from. It is always better to invest in safety now and get your workspaces professionally safeguarded.

Fire and explosions are no child’s game, which is why you should trust experts to equip you with the best precautionary measures available in the market. A small investment made now can save you money in repairs, replacements, and damages in the future—and provide peace of mind for years to come.

Fire & Explosion Damage

Working with industrial machines, high temperatures, volatile chemicals, and flammable materials is common in factories. However, these materials can be extremely dangerous and can cause devastating accidents, injuries, loss of life, and damage to assets—even when one exercises care. It is essential to equip a plant with the best safeguards and to understand the industrial terminology and classifications used for fire and explosion hazards.

There are zone classifications to determine how likely an explosive atmosphere is to occur in a given area, depending on the materials present:

- Zone 0 – An explosive atmosphere is present continuously or for long periods.

- Zone 1 – An explosive atmosphere is likely to occur occasionally during normal operation (e.g., during maintenance or venting).

- Zone 2 – An explosive atmosphere is not likely to occur in normal operation; if it does, it will persist only for a short period.

Dust Explosion Zones

For combustible dusts, areas are classified as Zones 20, 21, and 22:

- Zone 20 – A combustible dust cloud is present continuously, for long periods, or frequently.

- Zone 21 – A combustible dust cloud is likely to occur occasionally in normal operation.

- Zone 22 – A combustible dust cloud is not likely to occur in normal operation; if it does, it will persist only for a short period.

Dust explosions can occur due to static charge between particles or when a high concentration of dust in the air ignites in the presence of sufficient oxygen and an ignition source. The heat transfer generates a chain reaction, which can escalate into a large-scale explosion.

Here is how combustible dusts are classified by severity:

Combustible dusts are classified into four categories: St0, St1, St2, and St3. St0 is the lowest (no propagating explosion) and St3 is the highest severity.

| Classification* | KST value (bar·m/s)** |

|---|---|

| St0 | 0 |

| St1 | 1–200 |

| St2 | 201–300 |

| St3 | ≥301 |

* “St” stands for the German word “Staub” which means “dust”.

** KST, the deflagration index of a dust, is a generalized number used to estimate the anticipated behavior of a dust explosion. A higher KST value indicates higher explosion severity.

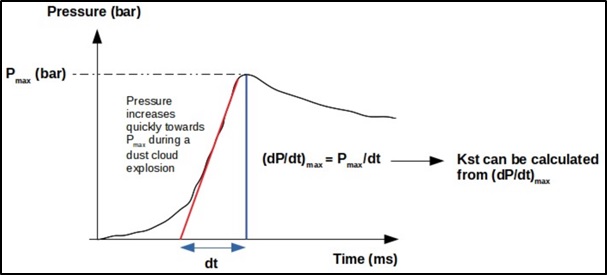

Apart from KST, there is also a value called Pmax (Maximum Explosion Overpressure), which indicates how much overpressure a particular dust concentration can develop in a closed vessel. The difference is that KST also considers the vessel size (via the V1/3 factor), while Pmax is the peak pressure attained.

When an explosion starts, fuel is initially abundant, combustion accelerates, and vessel pressure rises rapidly. Eventually the maximum rate of pressure rise is reached; as the fuel is consumed, the rate decreases. Relief vents or rupture discs must be sized to the expected explosion severity—the higher the maximum rate of pressure rise, the more severe the explosion.

How KST Is Calculated

KST = (dP/dt)max × V1/3 (units: bar·m/s)

From this, one can determine the required size of explosion vents or rupture discs needed to keep equipment and systems safe.