Why Your Powder Conveying System is Failing: Tips from a Trusted Supplier

Powder Conveying System

In powder handling, precision is not just a choice — it’s a necessity. Even the most sophisticated powder conveying systems can underperform if you don’t fully understand powder material behaviour at the design stage.

Imagine this: You’ve invested in top-tier equipment, meticulously planned every detail, but skipped a critical step — powder testing. What does that cost you?

- Unplanned Downtime: Studies show that up to 30% of plant downtime is due to flow-related issues, many of which could have been avoided with proper testing.

- Redesigns and Delays: Failing to test your powder beforehand can result in up to 6 months of delays for re-engineering and equipment replacements.

- Operational Failures: 50% of operational inefficiencies can be traced back to misjudged powder characteristics, leading to increased maintenance costs and unscheduled shutdowns.

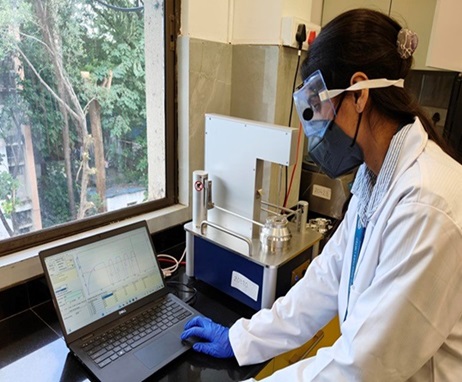

At RIECO, our simple design mantra is: “A system is only as good as its understanding of the material it handles.” That’s why we invested in our state-of-the-art Powder Testing Lab — designed to provide you with precise, reliable data on your materials before we even begin the design phase.

Why Powder Testing is Critical?

Powder behaviour varies significantly based on factors like particle size, moisture content, and flow characteristics. A powder that flows easily in one setup may cause significant issues in another. To avoid costly powder conveying failures, you need a precise understanding of how your materials behave under different conditions.

Key Benefits of Our Powder Testing Lab:

- Reduce Risk: Achieve over 40% fewer design revisions by understanding material behavior upfront.

- Enhanced Reliability: Design systems with 10% improved performance and reduced downtime.

- Optimized Efficiency: Accurately size equipment and optimize throughput with precise material data.

What We Test and Why It Matters?

Here are the key properties we analyse to ensure your system operates at its best:

- Bulk Density & Tapped Density: Ensures optimal sizing of hoppers, conveyors, and pneumatic systems.

- Particle Size Distribution: Predicts flow patterns, segregation risks, and dust issues.

- Angle of Repose: Helps identify flow issues like bridging or caking.

- Moisture Content: Crucial for flowability, product consistency, and storage stability.

- Powder Flow Under Stress: Crucial for defining geometry, sizing, and wall material selection in silos and hoppers.

- High-Precision Weighing: Guarantees accurate dosing and stable scale-up.

The RIECO Advantage: Test. Understand. Perform.

By choosing RIECO’s Powder Testing Lab, you gain more than just material data — you gain the confidence to design systems that work from day one. Here’s how we help:

- Accelerate time-to-market by ensuring your systems work right the first time.

- Minimize trial-and-error during commissioning, reducing costs by up to 25%.

- Seamless scale-up from lab to production, with fewer unexpected challenges.

- Lower operational disruptions caused by material flow issues.

- Make informed, data-backed design decisions that drive efficiency and profitability.

Ensure your next project has a reliable powder conveying system. Trust RIECO’s powder handling expertise to reduce downtime and maximize operational efficiency.

For queries or to know more get in touch with us at: https://www.rieco.com/contact-us