Understanding Rotary Airlock Valves: Features and Precautions to Maintain

Pneumatic Conveying System

Understanding Rotary Airlock Valves: Features and Precautions to Maintain

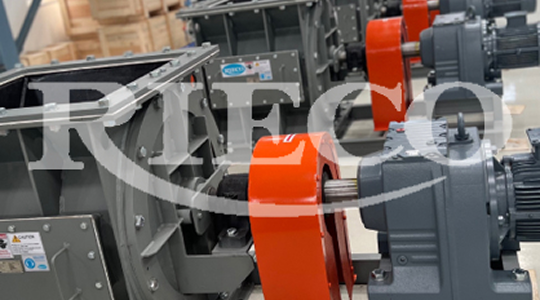

A rotary airlock valve forms an integral part of a pneumatic conveying system and is used where there is a requirement to minimize air loss while transferring material. A rotary air lock valve is adept in transferring materials such as bulk solids, powder, granules etc. in a system through to the next step in the process. Sometimes rotary airlock valves are also called rotary locks or rotary feeders. These valves ensure a controlled flow of bulk materials, prevent leakage and maintain air pressure.

These valves are of great help for applications that require frequent material change. A rotary airlock valve’s functioning depends upon its internal mechanism, its maintenance and the expertise imparted to it by a rotary airlock valve manufacturer. In this blog we will explore the features of a rotary air lock valve and precautions to maintain while using it.

Features to look at when choosing the right Rotary Air Lock Valve

1) Airtight Sealing

The key or primary function of a rotating air lock valve resides in its ability to maintain air pressure when the material is passing through to the pneumatic conveying system. The airtight sealing minimizes the pressure zone, and any potential leakage thus allowing the material to flow smoothly.

2) Efficiency of Rotating Vanes

The rotor blades’ speed and sharpness play a determining factor in final output incurred. The nature of metal with which the rotor blade is made also plays a determining factor in the process. Each metal consists of different properties and hence yields different results. A profitable and best choice would be to choose a rotary airlock valve which allows usage of various combinations of rotor vanes.

3) Optimized Design

A well-designed air lock rotary valve ensures minimal leakage of air. The design of a rotary airlock also determines the overall longevity and sustenance of the device. A poorly crafted design may lead to reduced resistance and increase the risk of leakage. An optimized design on the other hand will ensure right pressure and control in the pneumatic conveying system.

4) Seal Efficiency

The competence of a seal determines the pressure zone that will be created during the processing. An airtight or dust-tight seal creates the right pressure to avoid leakage of air. A rotary valve seal is made up of rubber, or other shock absorbent material that offers good flexibility and endurance. Additionally, a seal is a vital component of a rotary airlock which prevents contamination.

Precautions to Maintain for a Rotary Airlock Valve

Inspection: it is essential to conduct the necessary checks and inspections on any machinery, and a rotary airlock valve is no different. In the case of air lock rotary valve, a check needs to be done to see if there are any leaks, whether the rotor is functioning well devoid of any corrosion and if there are any signs of damage or tears in the seal.

Operational Precautions: the longevity of the airlock rotor depends upon endurance and resistance. An overload of material will hamper its functioning. Simultaneously, it is also essential to check the functioning of the components which constitute a rotary airlock valve. The components include headplates, housing, rotor and drive arrangement.

Safety Measures: The rotor blades of the rotary air lock valves have extremely sharp edges with the capability to cut hard materials. This makes it crucial for anyone working with it to take measures to avoid accidents.

Cleaning: If not cleaned at regular intervals the device may be clogged with particles and substitutes of the materials it passes. The power supply needs to be cut off first, then the rotor air lock valve can be dismantled and opened to rinse or wash.

Conclusion

Rotary Air Lock valves are critical mechanical devices when it comes to facilitating controlled movement of bulk solids or other materials. Their ability to handle a wide range of materials makes them a requisite across various industries such as cement, pharmaceutical, food, power etc. In addition to this, its precision and air pressure control mechanism, makes them a cost-effective measure and if taken appropriate care can sustain its functioning for a long time.

In the day and age when technologies are constantly upgrading and evolving RIECO believes in adapting and staying abreast with the latest innovations. Speaking specifically about rotary airlock valves, we are a rotary air lock manufacturer and hold expertise in manufacturing a wide range of pneumatic conveying valves.

To know more about our products and solutions, get in touch with us – https://www.rieco.com/contact-us