Why Air Pollution Control Systems Are a Must-Have in Cement Plants

Air Pollution Control

Cement production is one of the most energy-intensive and emission-heavy industrial activities. It generates significant amounts of dust, particulate matter (PM), nitrogen oxides (NOₓ), sulfur oxides (SO₂), and carbon dioxide (CO₂). To control these emissions and meet stringent environmental standards, air pollution control systems are essential. These systems not only protect the environment but also enhance plant efficiency, equipment life, and workforce safety.

What Are the Major Sources of Air Pollution in Cement Plants?

Cement plants emit pollutants at almost every stage of production. The key sources include:

- Raw material handling and grinding: Dust emissions from crushers, mills, and conveyors.

- Kiln operations: Major source of NOₓ, SO₂, and CO₂ due to high-temperature combustion.

- Clinker cooling and finish grinding: Generate fine particulate matter and heavy dust.

- Material storage and packaging: Fugitive dust emissions during transfer and loading.

Without proper control systems, these emissions can exceed permissible limits, impacting local air quality and leading to compliance violations.

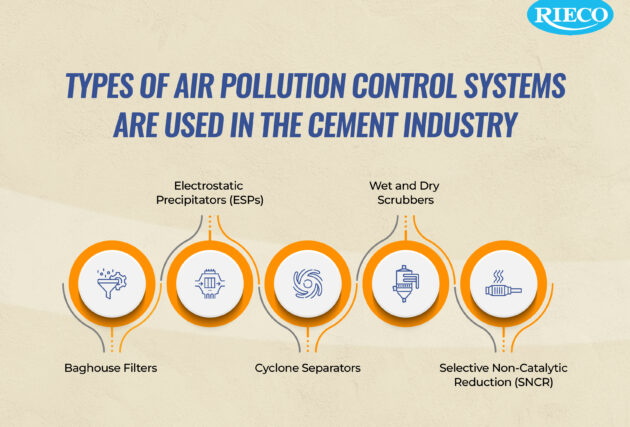

What Types of Air Pollution Control Systems Are Used in the Cement Industry?

Modern cement plants use a combination of mechanical, electrostatic, and chemical systems to minimise emissions. The main types include:

- Baghouse Filters (Fabric Filters): Capture fine dust particles using woven or felted filter bags.

- Electrostatic Precipitators (ESPs): Electrically charge and collect fine particulate matter.

- Cyclone Separators: Use centrifugal force to remove large dust particles before finer filtration.

- Wet and Dry Scrubbers: Remove acid gases such as SO₂ and HCl by neutralising them with reagents.

- Selective Non-Catalytic Reduction (SNCR): Reduces NOₓ emissions using ammonia or urea injection.

The right combination depends on kiln type, fuel used, emission norms, and local regulations.

How Do Baghouse Filters Work in Cement Dust Control?

Among all solutions, the baghouse filter is the most effective dust-control technology in cement plants. It operates by passing exhaust gases through fabric filter bags, which trap fine dust particles while allowing clean air to pass through.

Key features include:

- Removal efficiency up to 99.9% for particulate matter.

- Modular design adaptable to raw mills, kilns, and clinker coolers.

- Continuous cleaning using pulse-jet or reverse-air systems.

- Low operating pressure drop and long filter life with proper maintenance.

Baghouses are especially useful in regions with CPCB and GPCB emission norms, which typically limit dust levels to below 30 mg/Nm³.

How Do Cement Plants Ensure Compliance With Emission Standards?

Compliance is driven by environmental regulations set by bodies like the CPCB (Central Pollution Control Board) and State Pollution Control Boards (SPCBs).

Plants must install and maintain Continuous Emission Monitoring Systems (CEMS) to track parameters such as PM, SO₂, NOₓ, and CO₂ in real time.

Key compliance practices include:

- Routine filter inspections and replacement schedules.

- Integration of air pollution control systems with process control (SCADA).

- Proper handling and disposal of collected dust (reuse in clinker feed or safe landfilling).

- Regular audits to ensure emissions remain below regulatory limits.

What Are the Key Benefits of Modern Air Pollution Control Systems?

Implementing high-efficiency air pollution control systems provides both environmental and operational advantages:

1.Regulatory Compliance: Meet national and global air quality standards (e.g., CPCB, IFC).

2.Improved Workplace Safety: Minimised exposure to dust and harmful gases.

3.Equipment Longevity: Reduced wear and corrosion on downstream machinery.

4.Energy Efficiency: Optimised system design reduces fan load and power use.

5.Reputation and Sustainability: Positions the plant as a responsible and compliant manufacturer.

Conclusion

Cement plants play a vital role in infrastructure development, but also contribute heavily to industrial emissions. Investing in air pollution control systems, from baghouse filters and scrubbers to ESPs and CEMS, helps plants stay compliant, efficient, and sustainable.

With over 50 years of expertise, Rieco provides engineered Clean Air Solutions (CAS) tailored for cement plants, combining dust collection, filtration, and emission monitoring under one integrated system. If you’re planning an upgrade or facing compliance challenges, now is the time to evaluate your plant’s emission control setup.