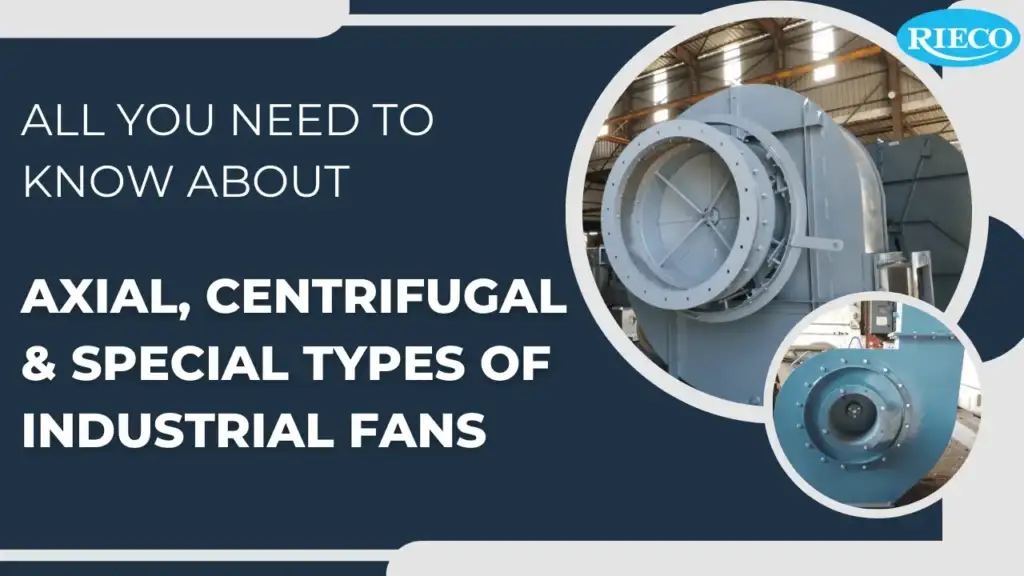

All you need to know about Industrial Fans: Different Types (Part1)

Blog

Industrial fans are an invaluable part of many processes, from providing ventilation and cooling for production plants to conveying tonnes of powders in various industries. With a variety of types, sizes, and designs available, industrial fans can help you create the exact airflow needed for your application. In this blog, we will explore the different types of industrial fans, the criteria to consider when selecting one, how to operate and install them, and the benefits they provide. With this knowledge, you can make sure you choose the right fan to meet your needs.

An industrial fan is a heavy-duty airflow device constructed from highly durable materials and components to withstand stringent environments and operate longer to provide constant airflow and pressure. Components of industrial fans include special bearings, enclosed motor housings, continuous welds, precisely machined impellers, and housings made of mild steel, cast aluminium, and stainless steel.

Types of Fans

Fans are classified into two types—axial and centrifugal—based on the nature of airflow through the impeller passage.

Axial Flow Fan: An axial fan pulls and blows air parallel to its shaft axis, which causes the air to transfer axially. There are three common axial types:

| Axial Flow Fans | Propeller Fans | Tube Axial Fans | Vane Axial Fans |

|---|---|---|---|

| Blade type | Narrow / propeller blade types | Narrow / propeller blade types | Airfoil blades |

| Impeller |  |

|

|

| Application | Move air against low resistances (less than 1 in. w.g.) | Move air against moderate pressures (less than 2 in. w.g.) | Higher efficiency; develops higher pressures (up to ~8 in. w.g.) |

| Features | Performance sensitive to added resistance; small increases can markedly reduce flow | Cylindrical housing; typically without straightening vanes | Cylindrical housing with straightening vanes on discharge side |

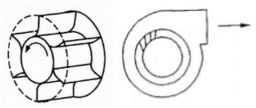

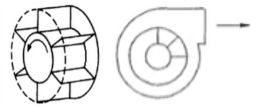

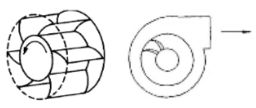

Centrifugal Fans: They displace air radially, changing the airflow direction by 90°. Centrifugal fans can generate relatively high pressures and are suitable for higher-pressure applications compared with axial fans. Common impeller designs are forward curved, radial, and backward inclined/backward curved.

| Centrifugal Fans | Forward Curved | Radial Impellers | Backward Curved |

|---|---|---|---|

| Blades | Curved toward direction of rotation | Straight / radial from hub | Inclined opposite to direction of rotation |

| Impeller |  |

|

|

| Features | Low space requirements; low tip speeds; low noise | Resist material build-up; medium tip speeds; medium noise; housings sized for conveying velocities | Higher tip speeds; high fan efficiency; low noise; non-overloading power characteristic near best efficiency point |

| Application | Low to moderate static pressures (HVAC, replacement air) | Exhaust systems handling clean or dirty air |

Single-thickness blades: handle light dust or moisture. Airfoil blades: higher efficiency, lower noise; hollow blades can erode faster with material and may fill with liquid in high humidity. |

Special Type Fans: In-line centrifugal fans use backward-inclined blades with special housings that permit straight-line duct installations. Pressure–flow–horsepower curves are similar to scroll-type centrifugal fans of the same blade type, while space requirements are similar to vane axial fans.

To conclude, industrial fans are essential due to their ability to regulate airflow, circulation, and air temperature. They come in a variety of shapes, sizes, and power levels to suit any application. Whether you need a large axial fan to move high volumes, a powerful centrifugal fan for long duct runs, or a compact inline fan for localized circulation, there is an industrial fan to meet your needs. With the right fan, you can keep workers, equipment, and materials safe and productive. Read the next blogs in the series: Crucial factors while choosing an industrial fan (Part 2) and Mastering fan selection, performance & installation (Part 3). Visit www.rieco.com to learn more about industrial fans and other equipment.