Introduction

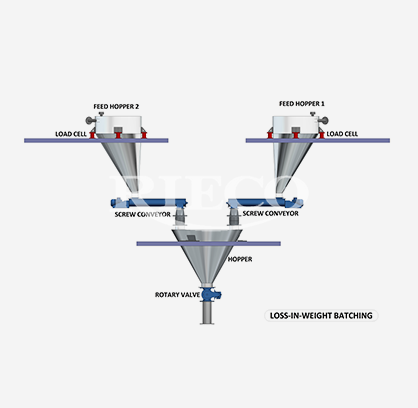

Over the years, the industrial sector has seen vast advancements, supported by revolutionary systems that have simplified and enhanced industrial operations. However, since a major part of industrial operations revolves around material handling and transport, it significantly needs more precision.

As a result, building a more trusted process that is safe and effective, handles a…