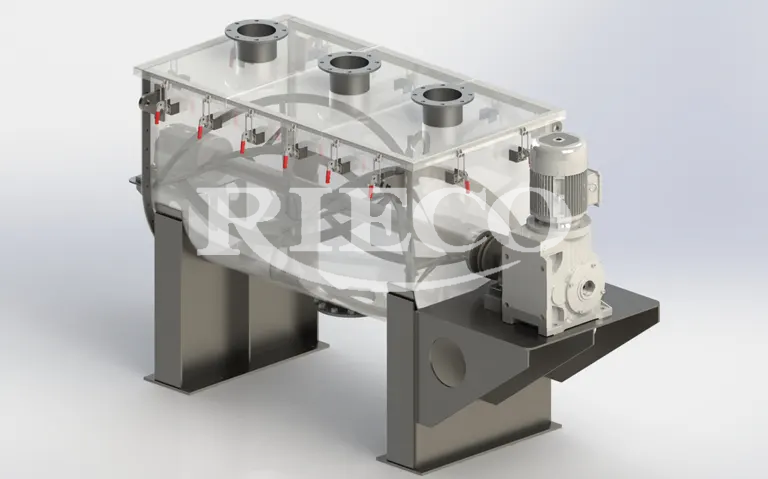

Ribbon Blender

Rieco's high-quality ribbon blenders, designed for the efficient, homogeneous blending of multiple powders. Designed for both shearing and mild kneading, the coordinated movement of our inner and outer ribbons guarantees thorough blending. Constructed from robust mild or stainless steel, our blenders are leak-proof and built to last. Catering to diverse needs, our range scales up to an impressive 12,500 litres in working volume. With Rieco, you're choosing durability and unparalleled blending efficiency.

Types

Single Ribbon Blenders

Single ribbon blenders, often known as a single shaft ribbon blender, consist of one helical ribbon agitator. This type of blender is ideal for blending bulk materials that don’t require a high degree of mixing precision.

Simpler Design: With only one ribbon, these blenders tend to have fewer parts and a simpler design, making maintenance easier.

Best For Coarse Blends: Ideal for materials that blend easily and don't require an intensive mix.

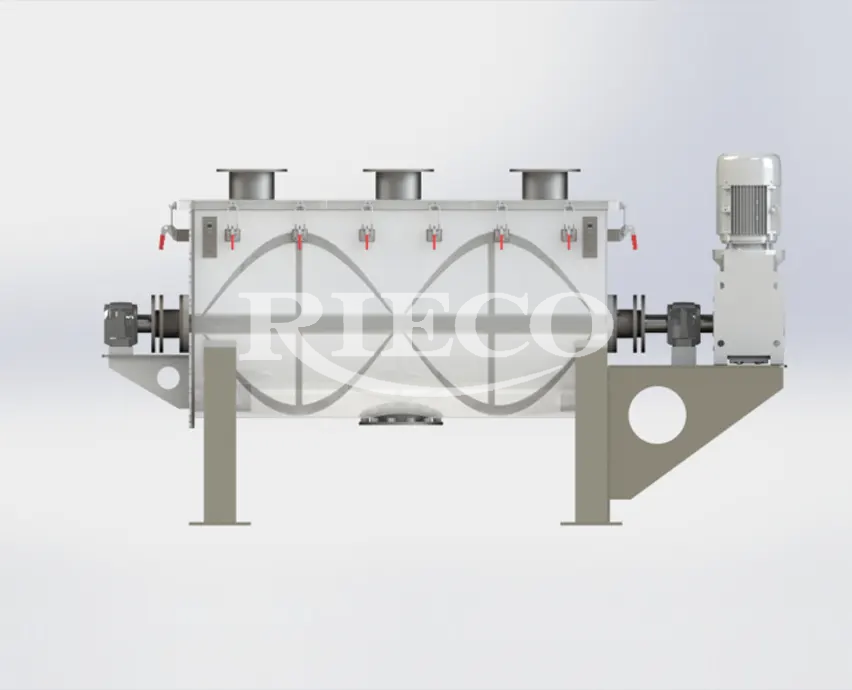

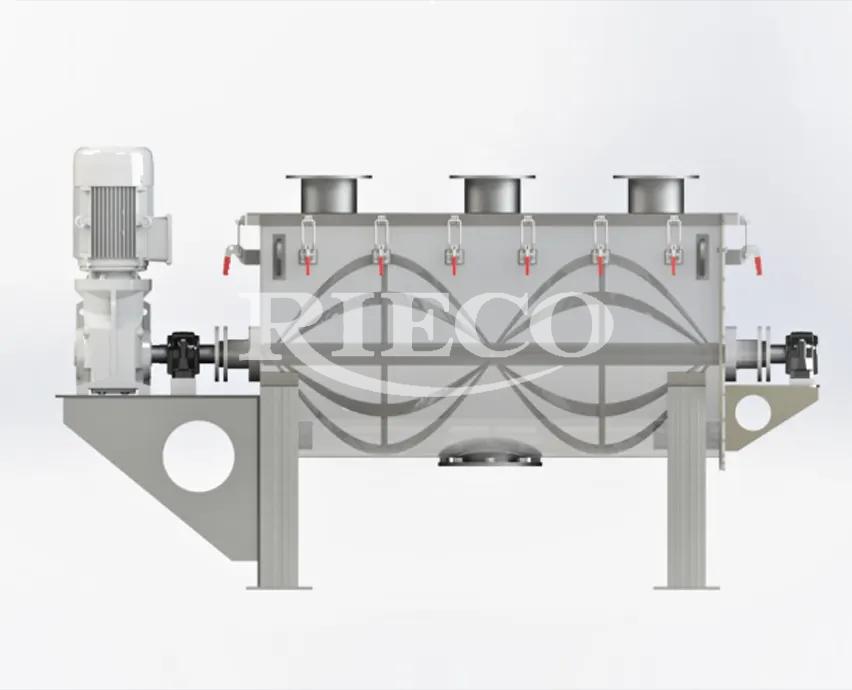

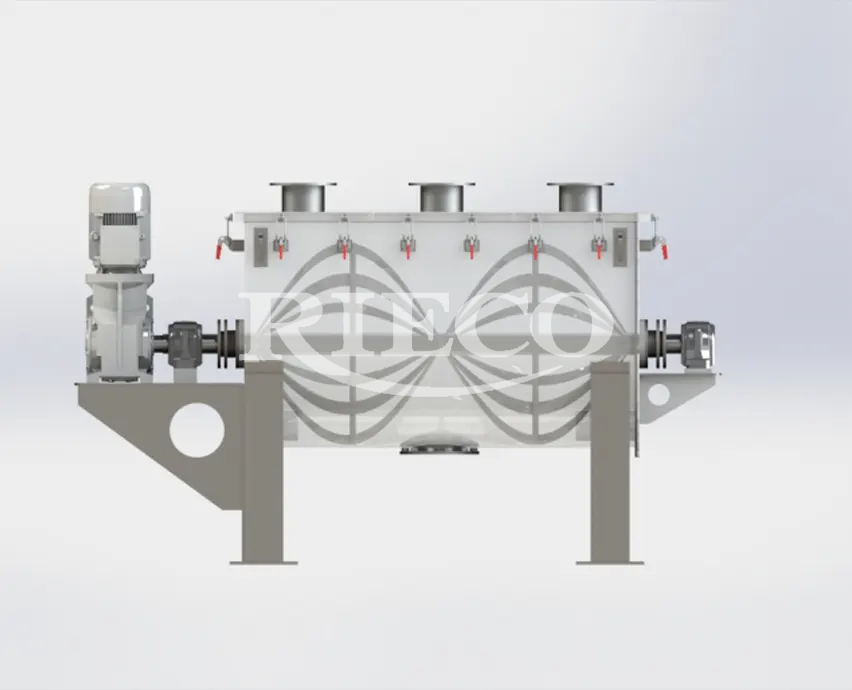

Double Ribbon Blenders

Double ribbon blenders feature two helical ribbon agitators on the same shaft: one inner and one outer ribbon. This design facilitates a balanced movement of material within the blender, ensuring a thorough mix.

Efficient Mixing: The dual ribbons promote consistent and uniform mixing by moving materials both radially and laterally.

Versatility: Suitable for a wide range of materials, from fine powders to coarse granules.

Optimal for Medium to High Viscosity Mixes: The double ribbon setup is great for mixes that require a higher degree of precision and uniformity.

Triple Ribbon Blenders

As the name suggests, triple ribbon blenders come equipped with three separate ribbon agitators. These are typically structured with one central ribbon and two side ribbons, providing an even more intensive mixing action.

Features

Intensive Mixing: The three ribbons ensure maximum material movement, resulting in a highly uniform mix.

Perfect for Difficult Blends: Especially useful for materials that are challenging to blend or require very fine and homogeneous mixing.

Increased Capacity: The extra ribbon allows for larger batch sizes without compromising mix quality.

- Volumetric capacities to suit specific applications with power ranging between 3-75 HP and volume capacity ranging between 300 litres to 12,500 litres.

- Tailor made designs available.

- Jacketed designs available for heating and cooling.

- Maximum mixing efficiency in leak-proof construction.

- Outboard bearings and stuffing box to prevent product contamination.

- Blender cum roaster (with thermal oil or electrical coil) for spices and blender cum cooler.

- Hot water circulation, steam circulation arrangement (for removing extra moisture)

- Chilled water circulation (for cooling product during blending)

- Blender with fluid coupling for power saving.

- Quick cleaning arrangement for hygiene and easy cleaning

- Oil/liquid spraying arrangements for suiting various application

- Blenders with sampling point arrangement for sample collection and testing before blender discharge.

- Blenders with load cells for batch weighing.

- Special designed blender that can function as live Silo.

Ribbon blenders are used across a spectrum of industries and applications, including

- Mixing of spices, dry flour, cocoa powder, and other culinary powders.

- Homogenizing different powdered ingredients for tablet preparation or other drug formulations.

- Combining various powdered compounds to create beauty and skincare products.

- Mixing of fertilizers, detergents, and other chemical powders.

- Creating a balanced mix of various feed ingredients.

Why Rieco?

in your process challenges.

we are happy to answer